Introduction

Have you ever marveled at the crystal-clear images produced by telescopes, microscopes, or cameras? Behind the scenes, there’s a critical component at work: the laser collimator. This powerful tool plays a vital role in aligning and calibrating optical systems, ensuring optimal precision and accuracy. In this comprehensive guide, we will dive deep into the world of laser collimators, exploring their functionality, applications, and the benefits they bring to various industries.

What is a Laser Collimator?

At its core, a laser collimator is a device that emits a narrow beam of light, typically in the form of a laser, to align and calibrate optical systems. By projecting a well-defined beam, laser collimators assist in aligning lenses, mirrors, and other optical elements precisely. They are widely used in astronomy, microscopy, photography, and industrial applications.

How Laser Collimators Work

Laser collimators operate on a simple yet ingenious principle. A laser diode, usually emitting a red or green light, is housed within the collimator body. The laser beam passes through a collimating lens, which converts the divergent laser beam into a parallel or nearly parallel beam.

The collimated laser beam then traverses through the optical system being aligned, striking the target surface or a reference point. The resulting reflection or scatter of the laser beam allows the user to determine the alignment and make necessary adjustments. By observing the position and movement of the laser beam, precise alignment can be achieved.

Types of Laser Collimators

Laser collimators come in various types, each tailored for specific applications and requirements. Let’s explore some of the most commonly used types:

- Newtonian Collimators: Designed specifically for Newtonian telescopes, these collimators assist in aligning the primary and secondary mirrors. They ensure the optical axis is centered and aligned with the telescope’s mechanical axis.

- Reflector Collimators: Reflector collimators are used to align the optical components of reflector telescopes. By accurately positioning the primary mirror and secondary mirror, these collimators help optimize the telescope’s performance.

- Refractor Collimators: Refractor collimators are designed for refractor telescopes, which utilize lenses instead of mirrors. These collimators ensure that the objective lens and other optical elements are aligned correctly, maximizing image quality.

- Camera Lens Collimators: Camera lens collimators are employed in the photography industry to calibrate and align camera lenses. They help eliminate focusing issues and ensure optimal image sharpness and clarity.

- Microscope Collimators: Microscope collimators are used in microscopy applications to align the various optical components of microscopes. They aid in achieving precise focus and improving the overall image quality.

- Industrial Collimators: Industrial collimators are versatile tools used in manufacturing and alignment processes. They are employed in applications such as laser cutting, welding, and optical system alignment in industrial equipment.

Benefits of Laser Collimators

The utilization of laser collimators offers numerous benefits across various industries. Let’s delve into some of the advantages they bring:

1. Enhanced Precision: Laser collimators provide unmatched precision in aligning optical systems. They allow for accurate adjustments and alignments, resulting in improved image quality and performance.

2. Time Efficiency: Laser collimators streamline the alignment process, saving valuable time. Their simplicity and ease of use enable quick adjustments, reducing downtime and maximizing productivity.

3. Cost Savings: By minimizing alignment errors and ensuring optimal performance, laser collimators help avoid costly rework and repairs. They contribute to increased equipment longevity and reduced maintenance expenses.

4. Versatility: Laser collimators find applications in a wide range of industries, including astronomy, microscopy, photography, and industrial manufacturing. Their versatility makes them indispensable tools for professionals across these fields.

5. Ease of Use: Laser collimators are designed to be user-friendly, even for those without extensive technical expertise. With clear alignment indicators and straightforward adjustments, they can be utilized by both beginners and seasoned professionals.

Laser Collimator Calibration and Alignment

To ensure accurate and reliable results, laser collimators themselves need to be calibrated and aligned periodically. This calibration process involves checking the collimator’s beam against known reference points or target surfaces. Here are the key steps involved in calibrating and aligning a laser collimator:

- Beam Alignment Check: Place the laser collimator in a stable mount or fixture. Align the collimator beam with a known reference point, such as a target or a designated mark.

- Beam Concentricity Verification: Use an appropriate tool or method to verify the concentricity of the laser beam with the collimator’s body. This ensures the beam is properly aligned within the collimator.

- Collimation Adjustment: If necessary, make collimation adjustments to align the beam and the collimator’s body precisely. Follow the manufacturer’s instructions for making these adjustments, as they may vary between models.

- Re-verification and Fine-tuning: After adjusting the collimator, re-check the beam alignment with the reference point or target surface. Fine-tune the adjustments as needed until optimal alignment is achieved.

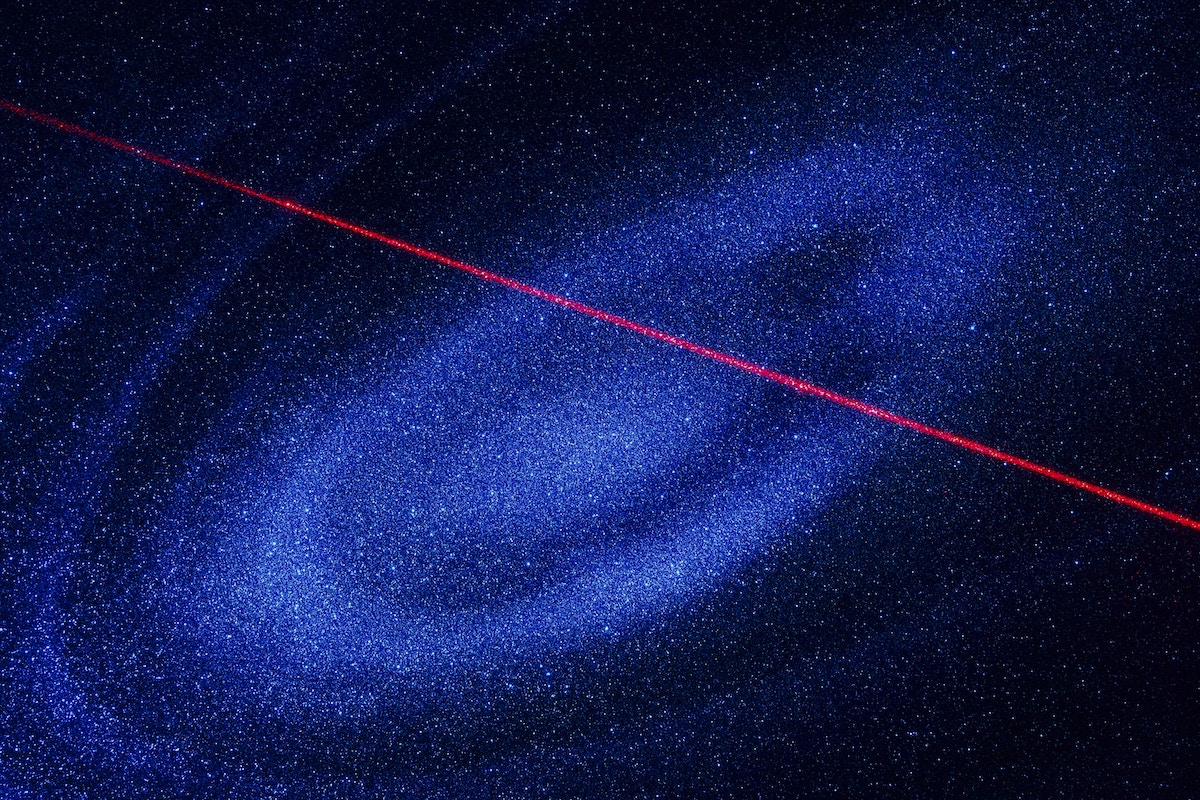

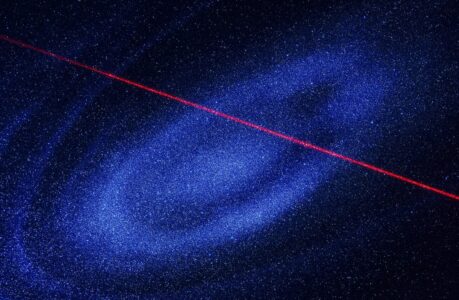

Laser Collimators in Astronomy

Astronomy is one field where laser collimators play a crucial role. Telescope alignment is paramount to capturing clear and detailed celestial images. Laser collimators aid astronomers in achieving precise alignment for both reflector and refractor telescopes.

For Newtonian telescopes, the primary and secondary mirrors need to be perfectly aligned along the optical axis. Laser collimators provide a convenient and accurate method for achieving this alignment. By projecting the laser beam onto a flat surface or a specialized target, astronomers can easily detect any misalignment and adjust the mirrors accordingly.

In refractor telescopes, laser collimators assist in aligning the objective lens and other optical elements. This alignment ensures optimal image quality, minimizing aberrations and distortions. With a laser collimator, astronomers can fine-tune the alignment, making the most of their telescopes’ capabilities.

Laser Collimators in Microscopy

In the field of microscopy, laser collimators are indispensable tools for achieving precise alignment and focus. Microscopes consist of intricate optical components that must be accurately aligned to capture clear and detailed images.

By employing a laser collimator, microscopists can ensure the objective lens, condenser, and other optical elements are properly aligned. This alignment minimizes spherical and chromatic aberrations, enhancing image quality. Laser collimators also aid in calibrating the focus mechanism, allowing for accurate and repeatable focusing.

Laser Collimators in Photography

Photographers rely on laser collimators to calibrate and align camera lenses, ensuring optimal image sharpness and focus. Laser collimators assist in eliminating front focus, back focus, or decentering issues that can occur with camera lenses.

By projecting the laser beam onto a flat surface, photographers can easily detect any misalignment and make the necessary adjustments. This calibration process saves valuable time and ensures that each photograph captures the intended subject with utmost clarity and sharpness.

Laser Collimators in Industrial Applications

In the industrial sector, laser collimators find widespread use in alignment processes and manufacturing applications. Laser cutting machines, welding systems, and other industrial equipment heavily rely on precise alignment for optimal performance.

Laser collimators aid in aligning optical systems within these industrial machines, ensuring accurate positioning and focus. They contribute to increased productivity, minimized material waste, and enhanced product quality. By using laser collimators, manufacturers can align their equipment quickly and efficiently, reducing downtime and maximizing overall efficiency.

Conclusion

Laser collimators play a pivotal role in aligning and calibrating optical systems across various industries. Their ability to provide enhanced precision, time efficiency, and cost savings makes them invaluable tools for professionals in astronomy, microscopy, photography, and industrial applications. By leveraging the power of laser collimators, professionals can unlock the full potential of their optical systems, capturing clear and detailed images, and achieving optimal performance.